Henan Taixing can design large maize flour milling plant according to your capacity demand, such as 100 TPD, 200 TPD, 300 TPD.

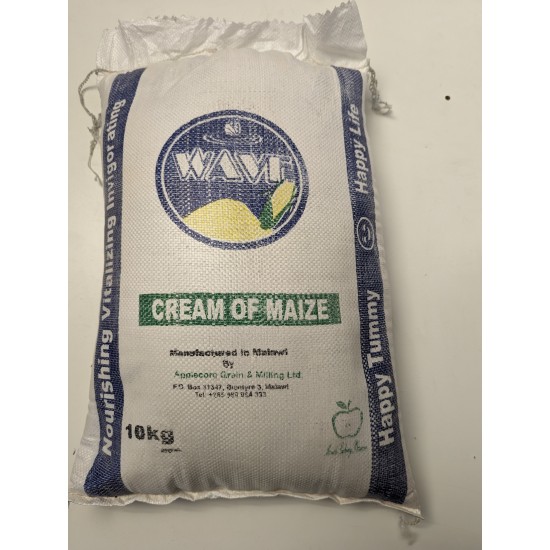

End products of Super Cream of Maize Flour Production Line :

(a). Super cream of maize (super fine maize flour)- from dehusked & degermed kernel where bran & germ are removed.

(b). Cream of maize (maize flour)- from dehusked maize

(c). Whole maize meal (roller meal) - from ungerminated & undehusked whole kernel

(d). By-products: Maize bran & impurities

The whole Cream of Maize Flour Production Line mainly includes:

stone and impurities removal, cleaning, peeling, germ removal and polishing, milling, plansifting, fortification equipment (micro additive machine), finished products (3 grades of maize flour) packaging, bran packaging, impurities packaging, vertical conveying, horizontal conveying, pneumatic conveying, ventilation and dust removal, electrical control, etc.

Features of Taixing Super Maize Meal Processing Line:

1. Equipment material: We will use high-quality steel plates. When purchasing raw materials, they will be tested with a spectrum analyzer before use;

2. Highly efficient gravity destoner and cleaning equipment ensure high quality of finished powder.

3. The peeling part adopts the specific corn peeling machines, which can greatly improve the corn peeling efficiency and reduce the corn crushing rate. The comprehensive yield rate of finished products is guaranteed.

4. The entire line is equipped with multi-section plansifters with good sealing and large sieving area, which improves the appearance of the entire production line and reduces dust in the workshop.

5. All dust removal in the workshop adopts pulse dust collectors, which have high dust removal efficiency and low failure rate, ensuring the dust reduction effect and the continuous operation of the production line.

6. Germ brushing machine: removes corn flour adhered to the outside of corn husks and germs, further increasing the output rate of corn flour and saving grain.

7. Pneumatic maize mill- core equipment: It has ultra-high grinding accuracy and no pollution to the environment. Shock absorption and noise reduction. Fine adjustment of rolling distance using cylinder locking. Core grinding and rolling distance grinding chamber air suction design solves the problem of powder spraying. The grinding operation is smooth and the quality is durable!

8. The whole line has reasonable and scientific design, high degree of automation, uniform and efficient discharging, low noise, good stability, safe and simple operation, and easy maintenance.