Fully Automatic Wheat Flour Mill Plant Introduction

Taixing Machinery are professional at designing and manufacturing Wheat Flour Milling Machinery plant, ranging from customized non-standard ones to standard configuration models that offer multiple combinations, we can all provide you with the perfect flour mill plant solutions for you. If you intend to setup a suitable flour mill plant, welcome to contact us for wheat flour milling equipment configuration solutions.

Applied Industries of Wheat Flour Milling Plant

Manufacturing Plant, Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops

30-40 TPD wheat flour mill plant

60 TPD Wheat Flour Production Line

Wheat Flour Miill Plant Capacities We Provide:

We supply wheat flour Line form 10 tons per day to 500 Tons Per Day.

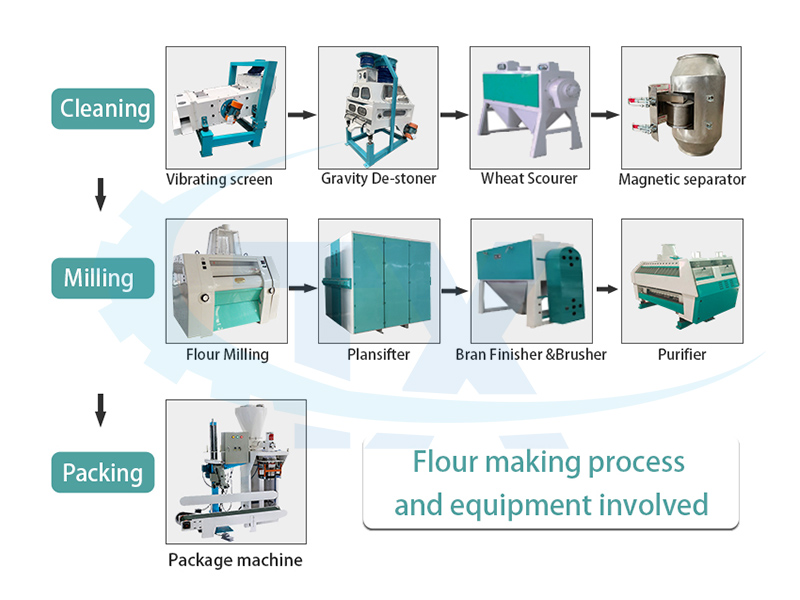

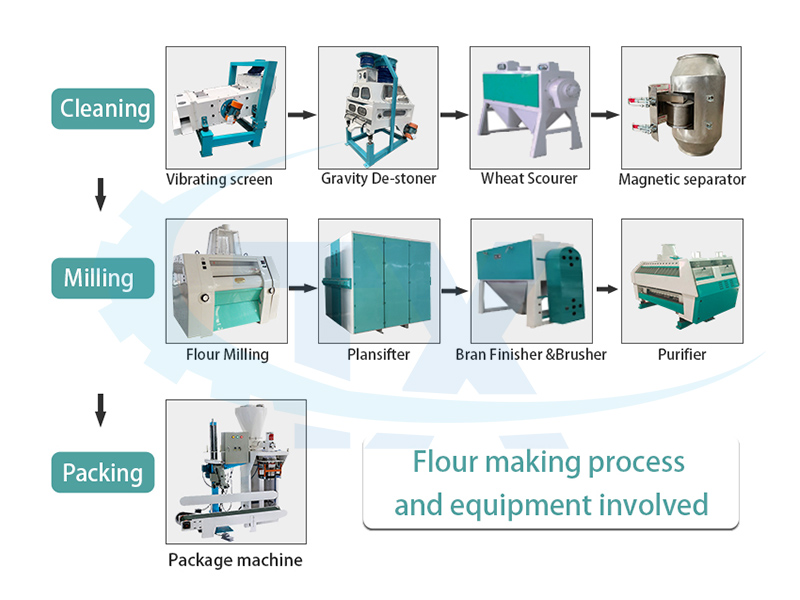

Wheat Flour Milling Process Introduction

Flour milling is a complex process of separating the endosperm from the bran and germ of the wheat kernel and then grinding the endosperm into flour, which is sifted to obtain flours of different qualities.

For manufacturing wheat flour, the main manufacturing process steps includes:

cleaning→watering→grinding→sieving grading→powdering→packaging, etc. (The specific process needs to be customized according to the actual needs of customers)

Wheat is cleaned before milling, and according to the different characteristics of the impurities, the corresponding cleaning equipment (such as plane rotary screen, stone remover, magnetic separator) is utilized to remove various impurities. Then the wheat is moisture adjusted, which is favorable to the later peeling as well as crushing.

Next, the wheat is fed into the milling system, and after a series of grinding by the hulling mill, dregs mill and core mill, and separation of pure flour grains, bran-containing flour grains and bran flakes by the clearing system, the final flour that meets the standard is extracted and sent for packaging.

Main Wheat Flour Milling Machines Included